Mechanical Properties of Gaskets

Compression-Rebound Performance

After understanding the testing methods for gasket compression and rebound, this article focuses on the compression rate and rebound rate of commonly used gasket materials, examining the performance differences among different materials and the key factors affecting the data.

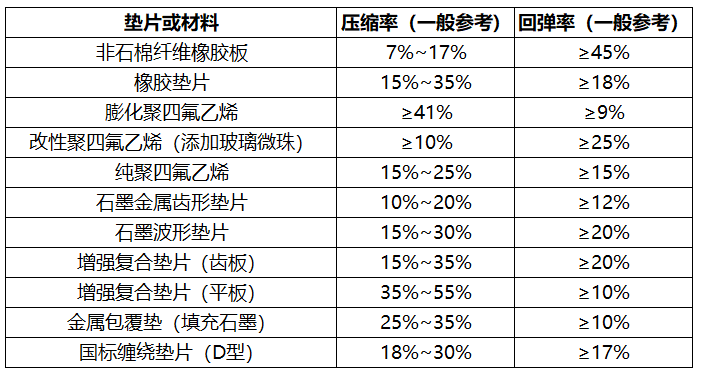

Commonly used gasket materials

compression rate and rebound rate

Gaskets of different materials and structures have significantly different performance ranges.

The compression rate is usually within a range. For example:

For non-asbestos fiber rubber sheets, the compression rate is 7%~17%, and the rebound rate is ≥45%.For rubber gaskets, the compression rate is 15%~35%, and the rebound rate is ≥18%.

BMC non-asbestos fiber: easy to cut, form and install

For expanded polytetrafluoroethylene (ePTFE) gaskets, the compression rate is ≥41%, and the rebound rate is ≥9%.Metal composite gaskets also have their own characteristics:For graphite-metal flat reinforced composite gaskets, the compression rate is 35%~55%, and the rebound rate is ≥10%.For national standard spiral wound gaskets (Type D), the compression rate is 18%~30%, and the rebound rate is ≥17%.

BMCSG: For high temperature resistant pipeline equipment flanges

These data are not fixed; they are also affected by factors such as temperature, thickness, and gasket stress. Therefore, in test standards, measurements are usually taken at room temperature in accordance with the specified thickness and gasket stress. However, for some special application scenarios, high-temperature tests are also required.

It should be noted that test data obtained using different test methods (e.g., ASTM F36, the GB/T 12622 Method A [indenter method], and the GB/T 12622 Method B [gasket method]) vary significantly. Thus, when comparing these test values, it is necessary to specify the test method used and clarify the inherent physical meaning.

Ingenious Seal Mastery

For sealing leakage issues, Baohua provides solutions. If you have any doubts about sealing technology, please pay attention to Suzhou Baohua and feel free to consult, comment, or leave a message! Thank you all! We will continue to talk about compression - recovery performance. See you next time!

Email:marketing@mybmc.com.cn

Email:marketing@mybmc.com.cn